Making the Grade…

/Hello Fellow Cheese Travelers!

In all my years within the cheese industry, the one thing I never had the opportunity to do is to make cheese…Oh, I have made my fair share of some fresh types at home (like Chèvre and Cottage Cheese)…but what I am talking about is working at a factory – Gently warming the local milk, adding in the starter culture until just the right moment when it’s time to add the rennet…

From there, time and patience become the most important ingredient. It is during this period that the “Milk Alchemy” happens as the liquid milk becomes a solid. From this point, the cheese maker will cut this cheese coagulum (also known as curd, or gel) with a wire harp until the curds reach the desired size and have released the right amount of moisture (see below).

Sounds dreamy….Right?

That’s what I thought too!…but then a team from Nugget Markets (my local retailer) actually flew back to Wisconsin to make that dream come true (in the form of lots of cheese!).

So, in this day and age where people are so disconnected where their food comes from…What cheese manufacturer would open their doors to let a team of cheese enthusiasts make their cheesiest dreams come true?...One word: Hennings

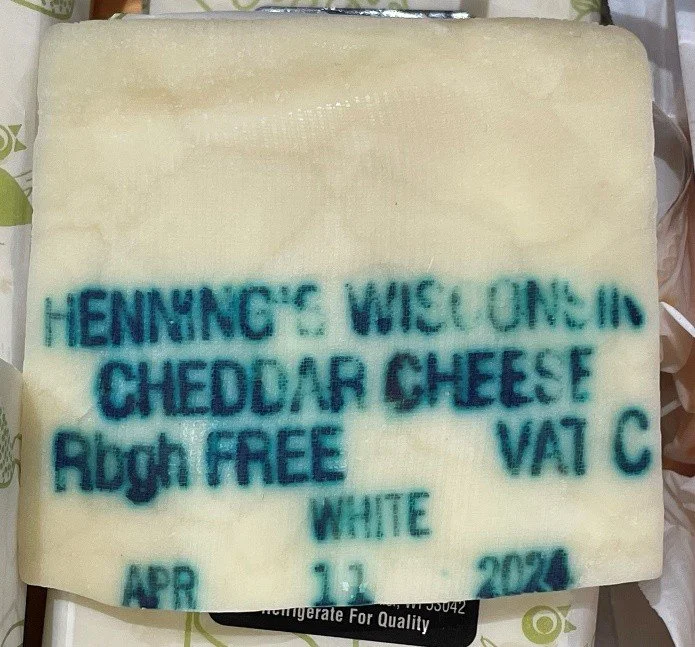

If the photo of the stamped cheese above wasn’t a complete give away, this cheese making adventure took place on April 11, 2024, at the Henning’s Cheese Plant in Kiel, Wisconsin (48 miles South of Green Bay).

The Nugget Market team, led by Jaclyn Neff, Director of Specialty Cheese, along with members of her team couldn’t be more excited to be personally welcomed to the Henning’s plant by Kerry Henning, grandson of the founder of Henning’s. Kerry has been making cheese “since he was old enough to lean over the vat” and is recognized as a Wisconsin Master Cheesemaker three times – Cheddar in 1999, Colby and Monterey Jack in 2002!!

The group was then treated to a tour of the facility by Kerry’s, brother Kert Henning

Both Kerry and Kert are the grandsons of the founder of the company – Otto Henning.

Image courtesy of Dairy Farmers of Wisconsin

Otto Henning was born on January 31, 1895, in the town of Schleswig, Wisconsin. He was the son of August and Louisa Henning. The family can be found on the 1900 Census, living on their farm with August’s parents who immigrated in 1869 from Germany when August was just a one-year-old.

Otto attended the district school and was a graduate of a short course in dairying from the University of Wisconsin. By the time the 1920 Census came around, Otto was a cheese maker, he was married, and had a daughter (Elvira) who was less than a year old.

Founded in 1914, Henning’s has been in business for 111 years and they are currently on their 4th generation of proud cheese makers.

The milk for Henning’s cheese today is sourced from seventeen dairy farms that are all within twenty-five miles of the plant. They make about 15,000 lbs. of cheese a day.

Now, back to our tour with Nugget Markets…

Photo courtesy of Jaclyn Neff, Nugget Markets

After a tour around the plant, it was time to get to work, as the plan was to make about 3,000 lbs. of cheddar…Some fresh cheese curds would be shipped to the stores within the first six months, but the rest was being held aside to mature even longer into blocks of cheddar and shipped out to the stores in celebration of their newest store grand opening on August 13th, 2025 – Their 17th location.

Once the team was ready to get to work, the large “closed vat” was filled with the warmed, pasteurized milk, then the starter culture was added – This gives the cheese its distinctive “cheddar” flavor…as well as breaks down the milk sugars (lactose) and converts them into Lactic Acid. The more Lactic Acid, the “tangier” the flavor. Microbial Rennet is added to start the coagulation process.

Once solidified, the cutting process begins with large cutting tools which rotate within the closed vat. This not only cuts the curds but stirs the curd/whey mixture as well.

Next, the curd/whey mixture is pumped into (what looks like an “open vat”) a piece of equipment called a “Finishing Table.” This “Table” allows the cheesemaker and the Nugget team to work from all sides of the table.

Photo Courtesy of jaclyn Neff, Nugget markets

The whey is then drained and large stainless steel “rakes” are used to push the curds to the outer edges of the vat creating two banks of cheese curds. These piles of curds are still warm and quickly stick back to one another, so using a large knife, this curd slab is cut into more manageable sized pieces, then stacked upon each other (also known as ‘Cheddaring’) to help press out even more whey.

Once the pH has reached the proper level, these slabs are then run through a mill, which returns them to the original ‘curd’ size. Warm water is then used to rinse excess fat from the curds, then dry salt is added over the curds which adds flavor, slows bacterial growth, as well as helps to expel even more whey.

From here, the curds were either packaged to sell in the stores, or the curd is placed into “hoops” (round, cylindrical containers) and filled, weighed, then pressure is applied to press out even more whey, as well as help “knit” the curds back into a solid block.

While many producers of cheddar cheese still make their cheddar in large blocks (over 500+ lbs.), Henning’s prefers to producer theirs in rounded drums…and they are still one of the few producers that make a variety of sizes – 12, 22, 38, 150, 300, and even up to 5000 lbs!

Cheddar is one of those cheeses that are checked along the aging process. First testing of the quality typically starts between three to ten weeks, but every cheddar maker has their preference.

Photo courtesy of Henning’s Cheese

A cheese grader will use a tool known as a “Cheese Trier” (which can look like an apple corer) to remove a small “plug.” The person doing the grading is looking for several key signs on how the cheese is developing:

· Appearance – The cheese grader will visually inspect the cheese to ensure that the coloring and body is correct, with no signs of defects or impurities. This inspection also gives the grader the ability to see how it is aging from the outside edge towards the center. Lastly, examining the back of the cheese trier can let the grader know the fat level in the cheese due to the residue left.

· Aroma – By smelling the cheese, the grader is taking note of the aromas and assessing them with the characteristics of that cheese type, as well as taking note of the positive descriptors (cream, sweet, nutty) depending on the type. While performing this exercise, they may also pick up negative descriptors (sour or ammonia).

· Touch – As the grader is using the trier to remove the “plug”, they can feel the density of the cheese and easy/firm it is; they can pinch some between their fingers to also find its density. Many graders will remove the plug from the trier to see/feel how flexible it is at this age.

· Taste – Does this first taste of cheese match up with its aroma? How is the “mouth-feel?”...is it creamy?...grainy? What other flavors are being picked up? – sweet, salty, bitter, sour, umami?

Aged wheel, or fresh curds - both delicious!

All of these notes can help the grader determine when this cheese is going to reach its peak. This could be months or years. Cheeses from batch to batch and season to season can differ greatly.

Though I am sorry that I missed this visit to the plant, I am grateful to experience the finished product and bring you this story.

Until next time,

Trevor, your Cheese Traveler